Advanced Printing Press Machine for Commercial Printing

December 10, 2025

The printing press machine operates at a steady speed, ensuring jobs do not slow down. The flow helps workers stay calm and sure. This makes each page look clean. The press gently moves ink, so no mess is created. With the smart and the smoothest controlling system you get so much easy control on your printing work. The printing quality is always best because of the advanced press materials in the machine. the machine daily without stopping.

Strong Print Path of Printing Press Machine

The print path ensures colors are positioned correctly. Each printing press machine holds firm, so sheets do not shake. This helps each print stay crisp. The extended frame gives each job the same look. The press remains cool, allowing the ink to dry clearly.

Top Advanced Printing Press Machines

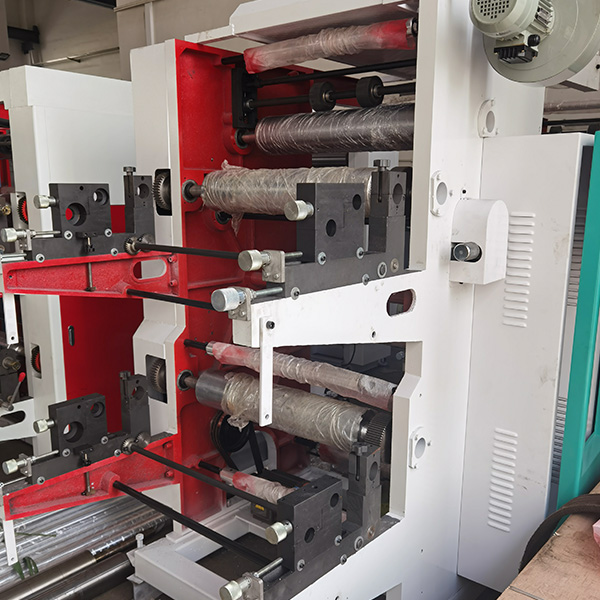

YF-FP2 Colors Flexographic Printing Machine

The YF-FP2 press works with two bright color decks. It prints fast and neatly. The frame stays firm, so each color stays in line. It is small but strong. It fits nicely in shops with tight spaces. It helps small runs look pro. The press also works well with PPE equipment catalog, Plastic molding machine parts, and other Plastic machinery parts, so your shop stays ready.

YF-FP4 Colors Flexographic Printing Machine

The YF-FP4 press has four color decks. It helps shops make bold prints with smooth blends. The colors stay soft and rich. The rollers move with calm speed. This makes each print look clean. It is ideal for shops that want to incorporate more color play. This press also supports the needs of plastic machine accessories suppliers and holds well with Plastic Injection molding supplies.

YF-FP6 Colors Flexographic Printing Machine

The YF-FP6 press features six full-color decks for deep tone builds. It prints wide jobs with rich blends. Each deck holds ink tightly. The press keeps sheets straight as they move. This helps each color land in the right spot. Shops that print big art or brand work love this model. It also links well with Plastic processing equipment accessories, Industrial plastic machine spares, and more.

Ink Care Steps

The ink trays remain tightly closed to prevent leaks. Each tray holds just the right amount. This ensures that color remains even on each sheet. Staff can clean the trays fast. That keeps the print line fresh.

Parts and Add-On Items

Shops may need strong parts like plastic extrusion equipment components, Auxiliary equipment for plastic machines, or spare parts for the plastic industry. With good parts, each press run is safe and reliable. Shops can also get Plastic machinery accessories catalog or talk with Plastic machinery accessories manufacturers to pick the right bits.

Extra Benefits of Printing Press Machine

Tools for Print Care

Staff can wipe parts fast. The trays lift out quick. The rolls come out smooth. This makes care work easy. Good care helps prints stay fresh. It also saves shops time.

Smooth Work Line

Each step from feed to roll stays firm. The print path does not shake. The ink stays smooth. The shop team can trust each step. This helps them plan jobs with ease.

Smart Print Setup

Each press starts fast. The ink warms quick. The rolls sync with each other. This enables each job to be ready in a short time. Shops save energy and time. They can take more orders with less stress.

Best Site to Buy the Printing Press Machines

For all print needs, Ruian Yunfeng Machinery Co., Ltd. is a top choice. They build strong and safe printing press machines. They offer the YF-FP2, YF-FP4, and YF-FP6 press lines. Their team helps shops pick the right model. Their tools work well with all key parts and add-ons. They give clear help when shops need it. If you want a press that stays strong for years, this is the best place to start.

For commercial grade printing the printing press machines are the top choice; it offers the best quality printings and quality. The machine is built with the most advanced technology which makes it easy to use and control.