| Category |

|

Other |

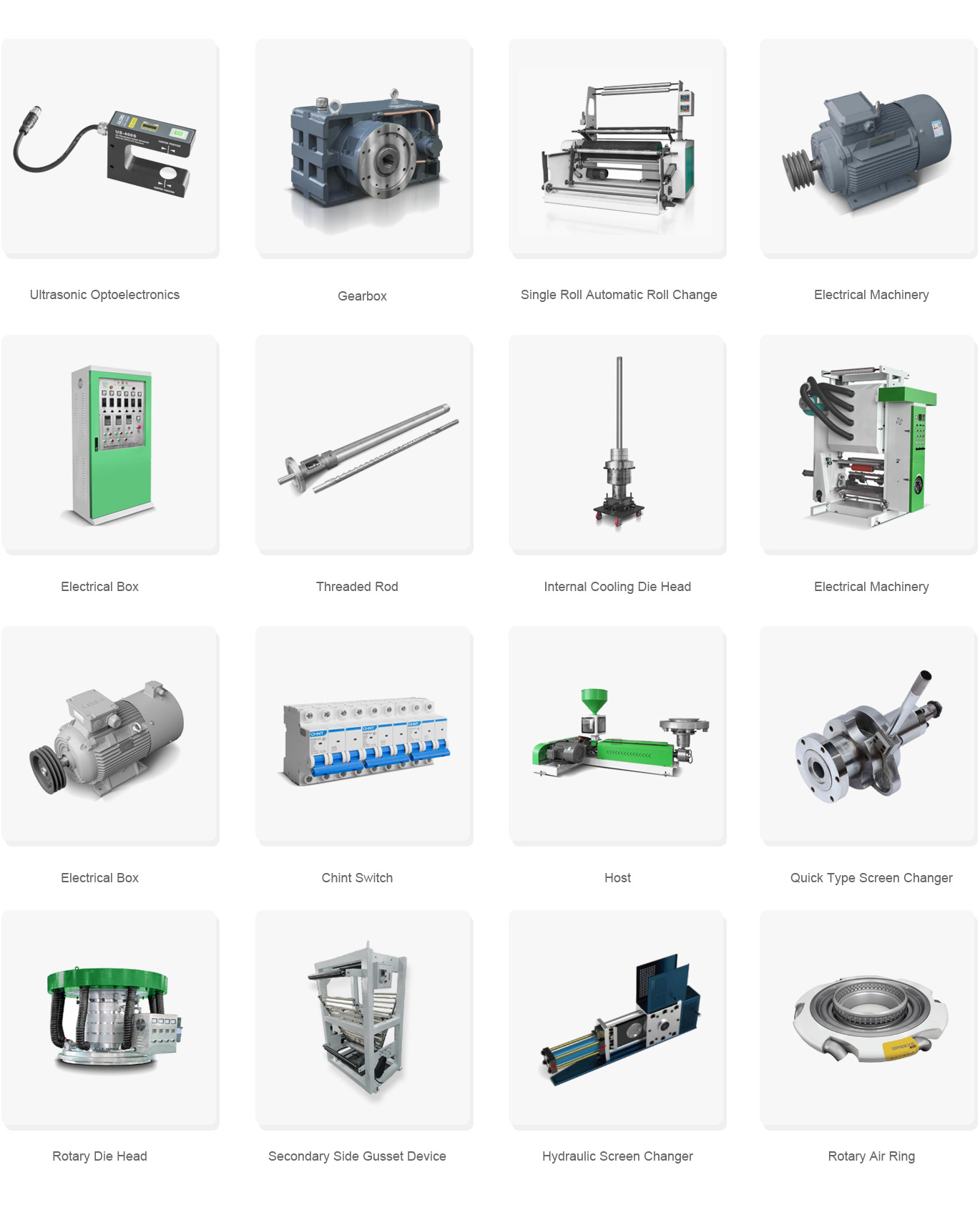

1.Screws

Optimized screw raises the extru-sion volume and using lifespan.Higher anti-corrupt and anti-grind ability |

|

Customized screw keyway and 30:1 or 32:1L/D double alloy screws with vacuum firetreatment. |

|

|

Only 28:1 or 30:1 L/D single alloy screw |

|

2.Motor

The motor operates with frequency conversion, which shows its advantages in terms of energy saving. |

|

Imported from American GE or Germany SIEMENS (with a three-year warranty). |

|

|

Other brands from China domestic market (with only one year warranty) |

|

3.Up-traction

The up-traction determines the Traction stability, plastic film flatness and embossing effect. |

|

5-rollers traction, one embossing roller, one bending roller, one polyurethane roller and two traction rollers. |

|

|

Three rollers or four rollers traction with normal rubber. |

|

4.Frame

The thick frame makes the machine more durable and reliable. |

|

The square tubes of machines are all thickened with a diameter of 120mm. |

|

|

The mainstream in the market is 80mm in diameter |

|

5.Gear Box

External circulation oil cooling system and hard tooth ensures the high working speed and lifespan of the gear joint. |

|

Xiaoshan brand hard tooth oil-cooled type, with filter, circulating oil and external cooling pump. |

|

|

Soft tooth gear box Other brands of from China domestic market without external oil cooling system . |

|

6.Heating

Advanced heating is much better in terms of life, heating speed and heat preservation effect than stainless steel heating. |

|

Aluminum heating, ceramic heating and more advanced infrared heating. |

|

|

Traditional stainless steel heating. |

|

7.Air ring

The structurally optimized high-speed air ring reduces the wind resistance and make the change of wind volume gentle. |

|

Italian designed high-speed double/ triple vent air ring. |

|

|

Normal single, double vent air ring from domestic market. |

|

8.Switch

cost-effective, high-quality materials, safety performance, diversified design and intelligent functions. |

|

Chint switches are cost-effective, high-quality materials, safety performance, diversified design and intelligent functions. |

|

|

The ordinary switch has low cost performance, general material, low safety performance and ordinary design. |

|

9.Production

5S management standards and high-end machining center equip Chaoxin with precision production capabilities and ensure product standards and quality. |

|

5S management modern standardized workshop. |

|

|

Traditional and chaotic production management. |

|